DIN gate valve type

Pressure seal type

Double disc type

High pressure gate valve type

Main Features :

Design standard: API 600、GOST、DIN、Client's standard.

Bolted bonnet &pressure seal bonnet.

Fexiable &solid wedge. Full wedge guiding (only for pressure gate valve).

Rising stem &Non-rising stem.

Full bore.

Easy opening/closing.

Bidirectional flow.

Friction between the disc wedge and the seat is small when operating valve,Which ensure the sealing is reliable.

Back-seat structure.

Optional By pass.

Production range:

Material: carbon steel, stainless steel, duplex stainless steel,alloy steel,Bronze.

Nominal diameter:1/2"~40"(DN15~1000).

Pressure range: Class150~2500(PN10~PN420).

End connection: RF, RTJ, BW.

Working temperature:-46℃~+560℃ .

Mode of operation: Hand wheel, gear box, Electric , Pneumatic , etc.

Pressure seal type

Integal flange type

Extend nipple type

Bronze material

Main Features :

Design standard: API 602、DIN、Client's standard.

Bolted bonnet &pressure seal bonnet.

Solid wedge.

Rising stem.

Seat could be hard-face &STL.

Full bore&Reduce bore.

Easy opening/closing.

Production range:

Material: carbon steel, stainless steel, duplex stainless steel,alloy steel,Bronze.

Seat material :Hardface/stl.

Size Range:1/2"~4"(DN15~DN100).

End Connection: RF,FF,RTJ, BW ,SW.

Pressure range: Class150~2500(PN16~PN420).

Working temperature:-46℃~+550℃ .

Operation: Wrench,electric, pneumatic, gas over oil actuator and electro-hydraulic actuator etc.

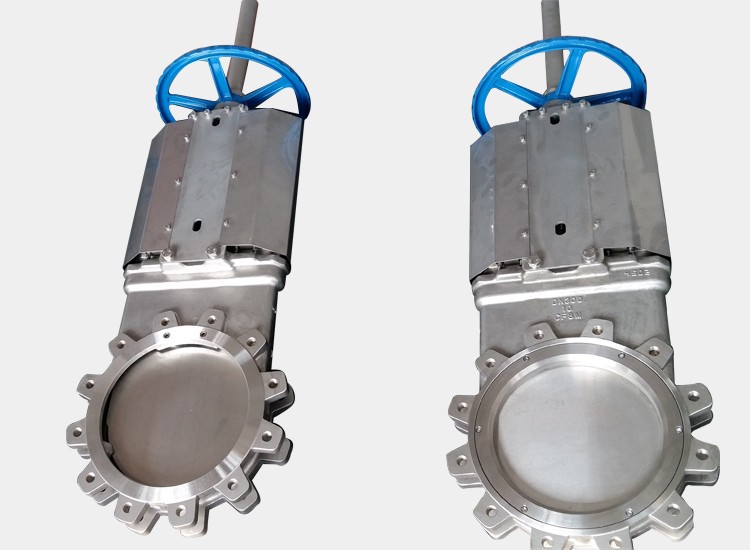

manual knife gate valve

Metal seat knife Edge valve

Lugged knife Edge gate valve

Resilient seat edge valve

Product Introduction :

Body material :Carbon Steel, Stainless Steel, Special Allory.

Gate material: Stainless Steel Chrome Plated, Special Allory.

Seat material: Stainless Steel+STL.

EPDM (120°C) /Viton(200°C)/PTFE(200°C) /NBR(90°C).

Size range: DN50~600mm NPS 2”-24” (Larger size on request).

Max Working Press :

DN50~DN250: 10Bar NPS2~NPS10:150Psi.

DN300~DN450: 7Bar NPS12~NPS18:90Psi.

DN500~DN600: 4Bar NPS20~NPS24:60Psi.

Temp. Range:-29...+800℃

Seal Tightness:According to MSS SP-81

Face to Face: MSS SP-81

Flange Standard:GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN1092-1

Applications:Pulp & Paper, Water Treatment,Beverage & Food,Fine Chemical, Power Planet,Steel Industry, etc.

Introduction :

The HPZ-Series Knife Edge Valve is a unidirectional wafer knife edge gate valve used on industrial pipeline for on-off operation.

The structure of body and seat eliminates clogging shutoff for flow with fine particles. Additionally, beveled knife edge helps

the gate cut through thick medium easily. According to different working situation: non-rising stem knife gate valve, wafer knife

gate valve, lugged knife gate valve, pneumatic knife gate valve, electric knife gate valve, manual knife gate valve and bevel

gear knife gate valve are all available.

Features :

Body:

a) Integral body with full bore structure ensures smooth flow, easy assembly and smaller shell leakage possibility.

b) Guide claws design at the port bottom for gate fixture, instead of a groove, eliminates any potential clogging when valve shutoff.

Gate:

a) Beveled knife edge provides strong cutting stress and tight sealing.

b) PTFE resilient point guider above the port prevents metal-metal contact between gate and body.

c) Gate thickness can be increased to meet higher pressure.

Seat:

a) Side-entry seat is replaceable, reducing the cost of maintenance.

b) Preloaded seat is adjustable to meet different sealing class and compensate normal seat wear.

Other:

a) Double thrust bearing minimize the torque required for operation

Through Going knife gate valve

O-Port knife Gate valve

manual though

manual through conduit knife gate valve

Product Introduction :

Body material :Carbon Steel, Stainless Steel, Special Allory

Gate material: Stainless Steel Chrome Plated, Special Allory

Seat material: Stainless Steel+STL

EPDM (120°C) /Viton(200°C)/PTFE(200°C) /NBR(90°C)

Size range: DN50~600mm NPS 2”-24” (Larger size on request)

Max Working Press :

DN50~DN250: 10Bar NPS2~NPS10:150Psi

DN300~DN450: 7Bar NPS12~NPS18:90Psi

DN500~DN600: 4Bar NPS20~NPS24:60Psi

Temp. Range: -29...+800℃

Seal Tightness: According to MSS SP-81

Face to Face:MSS SP-81

Flange Standard:GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN1092-1

Applications:Pulp & Paper, Water Treatment,Beverage & Food,Fine Chemical, Power Planet,Steel Industry, etc.

Introduction :

The HCPZ-series through conduit knife gate valve is a bi-directional wafer knife gate valve. It is mainly designed for highly concentrated flow media. With a through going O-port plate, this valve provides a stable and safe shut-off performance without clogging. With double-seat design, it can handle flow in both directions.

Features :

Body:

a) Full port design minimizes pressure drop and maximizes flow capacity.

b) Packing at both top and bottom eliminates leakage to surrounding.

Gate:

a) Though gate with o-port cut through a disc of media down when closing and return this portion back when opening.

This prevent media from clogging in the valve body cavity.

b) Gate thickness can be increased to handle higher working pressure.

c) Gate surface is well polished at both sides for tight seal and less jamming.

d) Gate is hard chrome coated for better abrasion resistance.

Seat:

a) Side-entry seat is replaceable, reducing the cost of maintenance.

b) Seat retainer covers the side of seat and prevents seat from direct flow flushing.

c) Preloaded seat is adjustable to meet different sealing class and compensate normal seat wear.

d) With seats on both sides, valve can handle flow in both directions 100%.

Other:

a) Double thrust bearing minimize the torque required for operation